Material Testing Lab Insights: Reveal the Scientific Research Behind Task Longevity

Wiki Article

Looking Into the Globe of Material Screening and Evaluation

Product testing and evaluation plays a vital function in countless sectors, from making to building. The devices made use of in product screening have actually progressed considerably, enabling engineers and scientists to acquire a much deeper understanding of the products they function with.Relevance of Material Testing

Product testing is a critical aspect of the design and production industries, making sure the high quality, dependability, and security of products made use of in numerous applications. The importance of product screening can not be overemphasized, as it plays a critical role in guaranteeing the efficiency and longevity of items and structures.Among the main factors for carrying out material testing is to analyze the mechanical properties of materials. This consists of determining their toughness, hardness, elasticity, and longevity. By subjecting materials to numerous mechanical examinations, designers can precisely examine their viability for specific applications and guarantee they fulfill the called for requirements and requirements.

One more vital element of product testing is the identification of potential defects or imperfections. By using non-destructive testing methods such as ultrasonic testing or aesthetic inspection, suppliers can identify any flaws that could compromise the architectural integrity or capability of the materials. This aids in protecting against expensive failings, mishaps, and prospective responsibilities.

Moreover, product screening also enables the assessment of material behavior under different environmental conditions. Aspects such as temperature level, humidity, and corrosive environments can significantly influence the efficiency and life-span of products. By subjecting them to ecological screening, engineers can assess their resistance to such problems and make notified choices regarding their viability for particular applications.

Common Strategies in Material Evaluation

Numerous strategies are frequently used in the evaluation of products to determine their residential or commercial properties and attributes. These methods play a crucial role in comprehending the habits and efficiency of products in various applications.Another commonly made use of technique is spectroscopy, which includes the communication of materials with electromagnetic radiation. For instance, infrared spectroscopy can recognize the functional groups existing in a product, while ultraviolet-visible spectroscopy can determine its optical residential properties. X-ray diffraction is one more effective strategy that permits scientists to analyze the crystal structure of products and recognize their stages.

Thermal analysis is likewise generally utilized to research the thermal behavior of materials. Differential scanning calorimetry, for example, can establish the melting factor and warm capacity of a material, while thermogravimetric analysis can measure its weight-loss as a function of temperature.

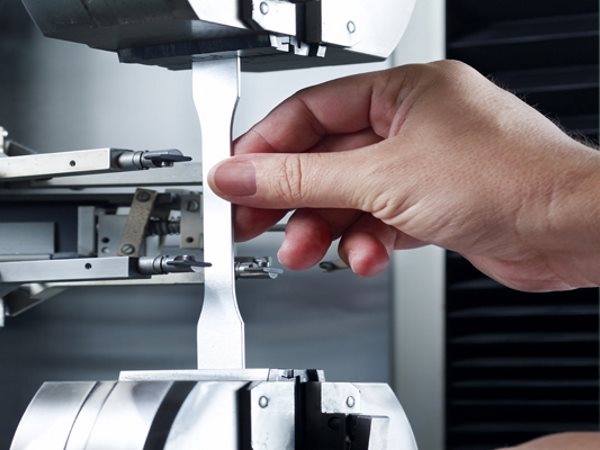

Moreover, mechanical screening is important to understand the mechanical residential properties of materials. Techniques such as tensile screening, firmness testing, and effect screening supply important information about a material's strength, stiffness, and toughness.

Tools Used in Product Testing

A range of specialized instruments and devices is employed in product testing to precisely examine the residential properties and habits of various materials. These tools are vital for performing experiments and acquiring reputable data in different industries, consisting of aerospace, automotive, building and construction, and production.One of the most usual tools utilized in material screening is the global testing device (UTM) One more essential instrument is the solidity tester, which determines a material's resistance to imprint or infiltration.

Additionally, thermal analysis tools, consisting of differential scanning calorimeters (DSC) and thermogravimetric analyzers (TGA), are made use of to investigate the thermal buildings and actions of products, such as melting factors, glass changes, and decay temperature levels.

Applications of Product Screening and Evaluation

To totally use the beneficial information gotten via using specialized tools and why not check here tools in product testing, it is necessary to explore the wide variety of applications where this analysis can be used. Product screening and analysis play a critical duty in numerous markets, including aerospace, automobile, building, and manufacturing.In the aerospace industry, material screening and evaluation are utilized to make sure the safety and reliability of airplane parts. material testing lab. By subjecting products to extreme problems, such as high temperature levels and pressures, engineers can analyze their efficiency and make notified decisions regarding their suitability for usage in aircraft

In the vehicle market, material testing and analysis are employed to boost the resilience and performance of lorries. By examining the residential properties of various materials, suppliers can establish stronger and lighter parts, causing boosted fuel performance and general vehicle efficiency.

In the building sector, product testing and evaluation are utilized to make certain the structural honesty of structures and facilities - material testing lab. By assessing the toughness and resilience of building and construction materials, designers can develop structures that can withstand environmental problems and different loads, making sure the safety of passengers

In the production industry, material testing and evaluation are essential for quality assurance objectives. By analyzing the buildings of raw materials and completed products, suppliers can identify any weaknesses or problems, permitting them to make essential renovations and deliver premium products to customers.

Future Fads in Product Testing and Evaluation

Arising modern technologies are improving the area of material screening and evaluation, revolutionizing the method sectors assess and maximize the performance of products. As innovation proceeds to breakthrough, brand-new trends are emerging that are expected to additionally improve the abilities of product screening and analysis.Among the crucial future patterns in material testing and analysis is using artificial knowledge (AI) and artificial intelligence (ML) formulas. These innovations can assist in automating the analysis process, allowing for faster and much more accurate results. AI and ML can additionally aid in recognizing patterns and patterns in big datasets, allowing researchers to make more enlightened choices.

One more trend is the advancement of advanced non-destructive screening (NDT) strategies. NDT techniques, such as ultrasonic testing and thermal imaging, are becoming extra advanced, permitting the detection of flaws and issues in products without the need for destructive testing. why not try these out This not just conserves time and resources yet additionally makes sure the integrity of the tested materials.

Additionally, there is a growing passion in nanotechnology and its effect on material screening and analysis. Nanomaterials display one-of-a-kind buildings that differ from their bulk equivalents, and specialized techniques are being created to examine and characterize these products at the nanoscale.

Conclusion

Finally, material screening and analysis is a vital facet of different sectors and research study areas. It enables for the analysis and understanding of material homes, ensuring high quality and safety in different applications. Usual methods and tools are used to perform these tests, supplying valuable insights and data. As technology remains to breakthrough, future trends in material screening and evaluation are expected to better enhance accuracy, performance, and innovation in this area.

Report this wiki page